MAG-Feed-Hopper

The MAG-FEED-HOPPER is a material buffer, which continuously, feeds a system through dosing. Due to its geometry it is also suitable for very viscous materials. Thanks to the system design, the buffer volume can be adapted to the desired requirements.

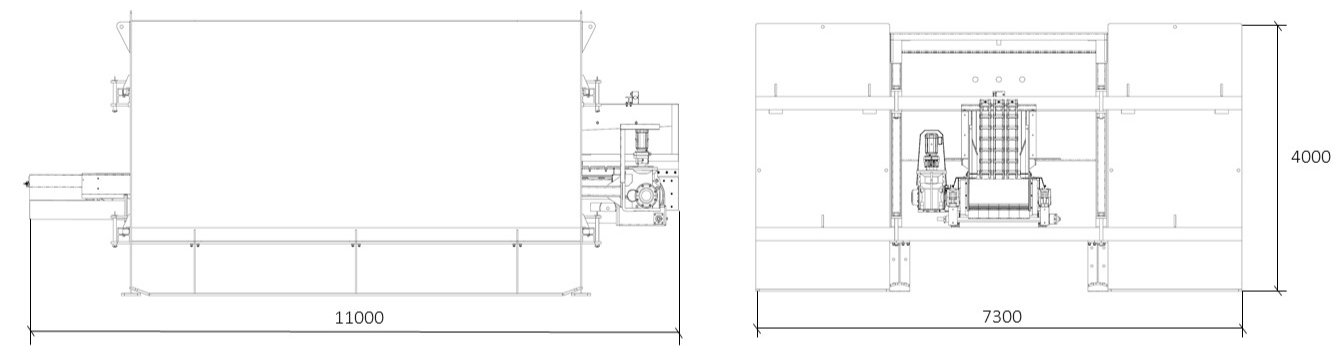

The feed hopper is available in a stationary or semi-mobile design.

- Buffer volume (optional):

Lower part 15 m³

with upper part small 23 m³

with upper part large 35 m³

+ 4 m³ with MAG-GRIZZLEY-SCREEN low

+ 9 m³ with MAG-GRIZZLEY-SCREEN high - Conveying capacity 30-200 m³/h

(depending on gearbox and motor) - Feed grain 0-400mm

- Drive power 3-4 kW (dep. on gearbox and motor)

How it works

The material is fed into the bunker by wheel loaders or tippers. Suspended wedges prevent excessive material pressure on the belt and prevent blockages. The bunker design ensures a uniform removal and reduces caking. With its running speed, the belt conveys the desired volume flow to the downstream system. A signal is transmitted to the controller when the belt is idling.

Design

The feed hopper is built as a stable, sheet metal hopper with a strong profile frame. The wear surfaces are lined with 10mm Hardox plates. The discharge conveyor is equipped with rollers in the centre and slideways under the sealing edge. The sealing gap can be adjusted. The feed hopper is modularly compatible with the MAG-GRIZZLEY-SCREEN.

Characteristics of the semi-mobile version

The semi mobile feed hopper is framed in a fabricated steel construction and equipped with runners, which enable on-site towing. Lateral wing walls serve as a material box for the oversized grain and as a barrier to the filling ramp. The wing walls can be removed and reattached relatively easily for moving. The semi-mobile feed hopper is compatible with the MAG-GRIZZLEY-SCREEN.