MAG-Sizer

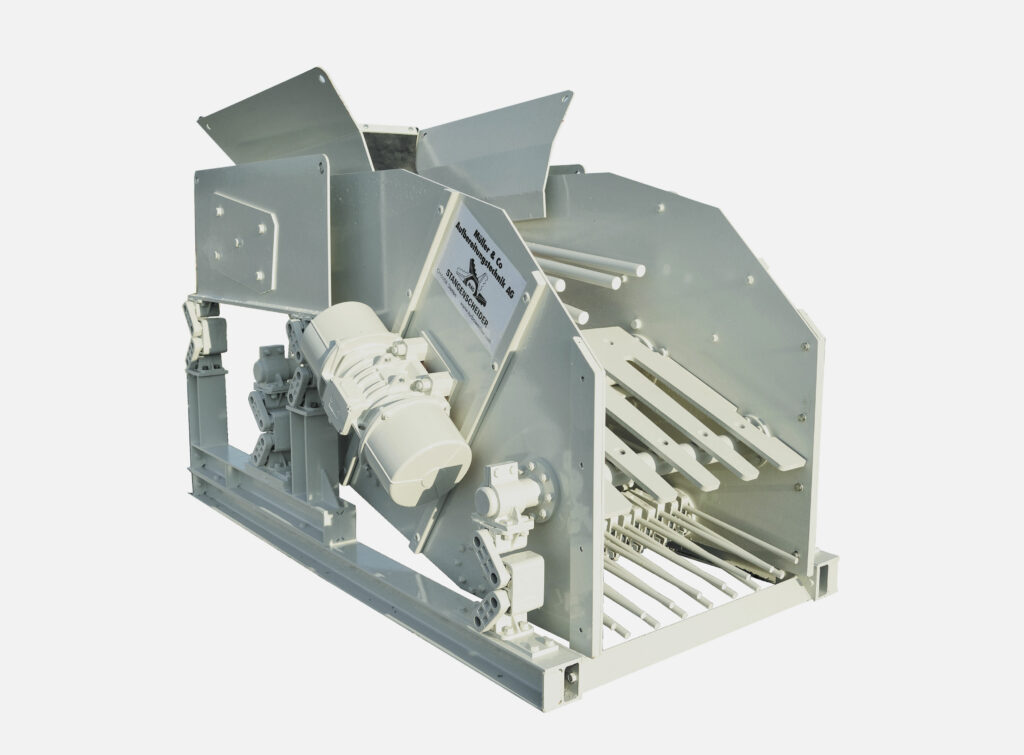

The task of the MAG-SIZER is the pre-separation of oversized grains before the washing process. Due to its two-part design, it is also suitable for very viscous materials, which can be processed evenly in batches. The device is characterised by its low susceptibility to pluggable grains and its compact, low-wear design.

- Capacity up to 100-120 t/h (sticky material)

- Separation cut approx. 70-100mm (one-dimensional)

- Feed grain 0-400mm

- Drive power 3x 3.2kW

How it works

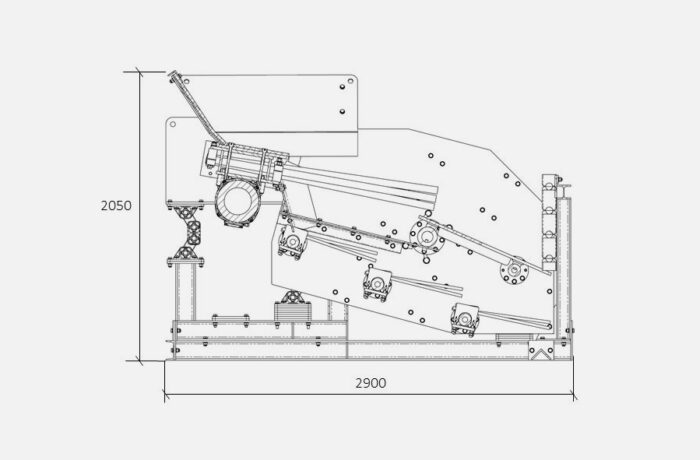

Feeding takes place with a conveyor or feed hopper discharge belt directly into the hopper of the upper deck. The material is then continuously conveyed over the first bar deck. The material is loosened and oversized stones are removed. On the lower deck, the actual cut is made with three successive rows of bars. The screened grains are discharged to the front, with the washable material falling down.

Design

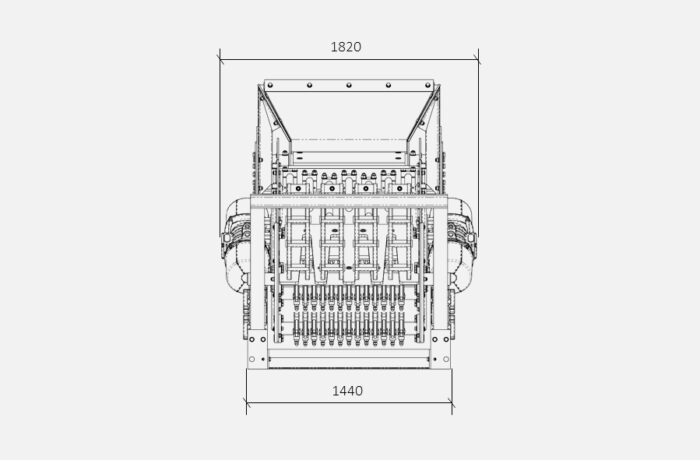

The machine is constructed in two parts, whereby the upper part moves in a circular motion and the lower part in a linear motion. By clamping the bars on the decks, they are easy to replace. The inclination and seperation cut of the bars on the lower deck can be adjusted thanks to the clamps. The sheet metal construction is mainly made of Hardox. A curtain of chains slows down accelerated oversized particles before they exit.