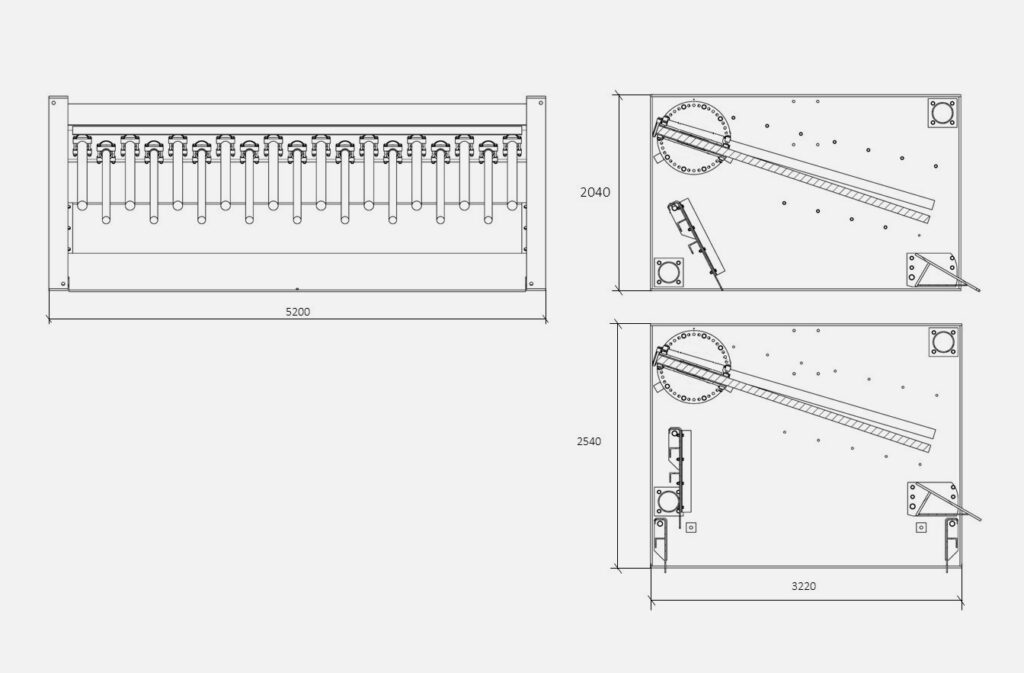

MAG-Grizzley-Screen

The MAG-GRIZZLEY-SCREEN is the first step of separation and protects the following parts of the system from oversized grain. Due to the special arrangement of the bars, it has a low susceptibility to blinding. There is additional buffer volume for the feed material in the bar sizer.

- separating cut at approx. 250-320 mm (one-dimensional)

- Feed grain up to approx. 1000 mm or 2 t

- Buffer volume:

4 m³ MAG-GRIZZLEY-SCREEN low

9 m³ MAG-GRIZZLEY-SCREEN high - Loading by dumper or truck possible

How it works

The material is fed into the ends of the bars by the wheel loader or tipper. Due to the dynamics and gravity, oversized grain is separated from the rest of the material by the bars. The coarse grain is ejected to the front and the processable material reaches the buffer volume of the feed hopper.

Design

The bar sizer has a stable cross beam with solid side walls. Depending on the application, the separation cut is selected via the bar spacing and the design. The bars are clamped and can therefore be easily exchanged. The sizer inclination can be adapted to the material behaviour and can be adjusted in 3° increments. Pivoting deflector plates allow flexible material feed depending on the type of feed hopper. The bar sizer is available in a low (2000) or high (2500) version and is compatible with the MAG-FEED-HOPPER in a modular system.